Industrial Automation Software Development

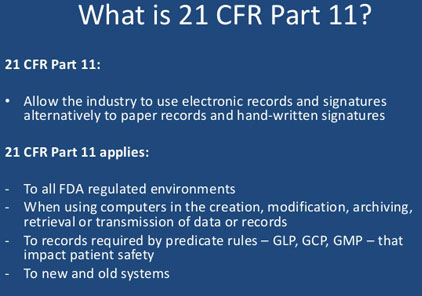

Paryana Automation niche technical expertise in terms of Designing to Development to Implementation is in the field of Industrial Automation Software Development. We have a unique combination of understanding the process of development as well as the Device Interface aspect in the Industrial Automation Field. If you are an OEM of Devices which can communicate over specific Protocols like Serial, TCP/IP, ASCII etc. or you have imported Devices for which you want to develop Data Logging, Data Writing, Data Analysis Software then we have that expertise to do that. We study the Protocol over which the Devices can communicate and accordingly we do various functions in our Software. We have in depth understanding in Pharma Industry in developing software which will be Pharma Part 21 CFR Compliant which is the norm of the Pharma Industry. Our Software is often validated by third party for testing an certifications. Device Interface is just one step, from there, we have mastered ourselves in other areas of Industrial Automation Software Development like: PC Based Data Logging Applications, Web Based Data Logging Applications, OPC Interface Applications, Customized Device Interface Applications, Bridging & Reporting Applications, Intelligent Building Management Systems (IBMS), SMS / Email Applications, Dongle Integration, Project Design etc.

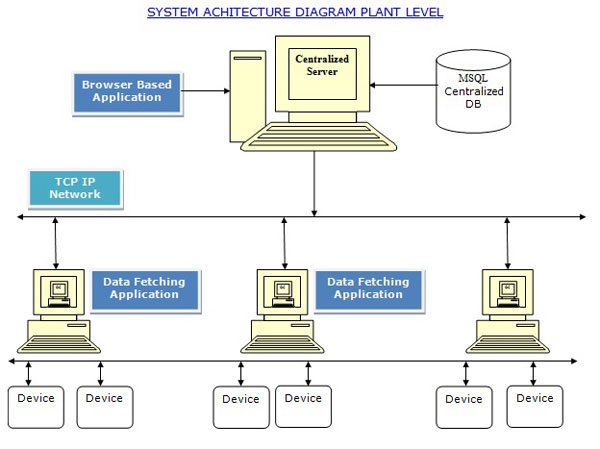

We have worked with Equipment Manufacturers, Automation Project Companies, Project Consultants and Corporates in such Application Development. We have not only the development capability of Desktop Based Applications but can make Web Enabled Applications allowing you to have a complete Web Based Interface in Automation Project. We are experts in Reporting and Bridging Applications where there can be multiple types of inputs like PLC, OPC, Database, Serial Port, TCP/IP, xls file system, csv file system, FTP, Device etc. and having our Application as a Bridge, we can compute and work on data and convert/send them to other type of outputs; again like anyone of the names mentioned in inputs. Such complex bridge applications are required in Complex Industrial Processes. Again by using any of the Inputs like PLC, OPC, Database, Serial Port, TCP/IP, xls file system, csv file system, FTP, Device etc we can compute/work out on the data received and save them in our database and generate various types of Analysis Reports on the same.

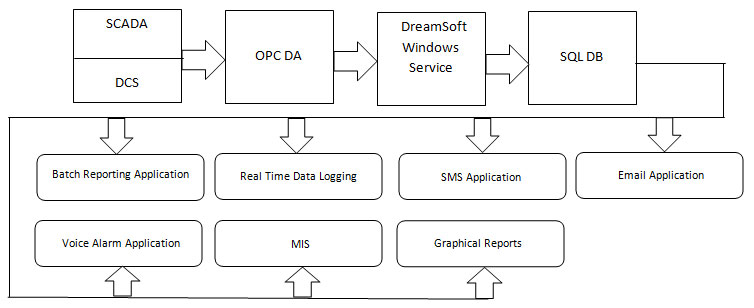

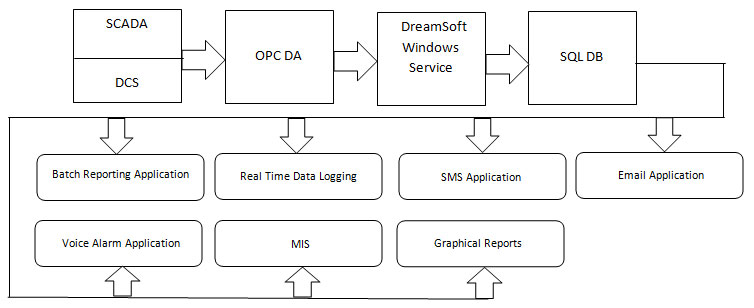

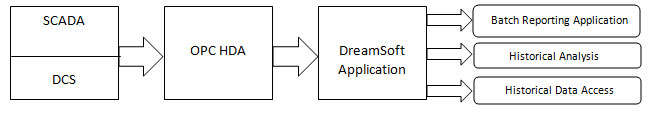

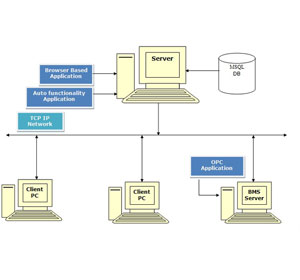

We have worked on Projects and Complex Applications in countries like USA, Far East (Vietnam, Singapore etc.) and India. In Far East countries we have worked and mastered our understanding of OPC which is a Software Interface Standard that allows Windows Programs to communicate with Industrial Hardware Devices. OPC is implemented in server/client pairs. The OPC server is a software program that converts the hardware communication protocol used by a PLC into the OPC protocol. The OPC client software is any program that needs to connect to the hardware, such as an HMI. The OPC client uses the OPC server to get data from or send commands to the hardware. We have worked extensively on OPC Interfaces in Projects.

With such vast experience in the fields of Industrial Automation Software Development, we are now in a position to design the complete end to end System for the Client including suggesting them which hardware to use for the betterment of the results and output of the Project.

Apart from our own technical expertise, we have dedicated team of Programmers who are well versed with the technologies in these fields and can develop complex software and applications and also can support client on site and understand their issues in dealing with problems.

This section will take you through an interesting modules of Industrial Automation Software Development.

- Data Logging Applications

- OPC Interface Applications

- Bridging & Reporting Applications

- Customized Device Interface Applications

- SMS / Email / Voice Alarm Applications

- Project Design

- Part 21 CFR Highlights

- Protocols

Data Logging Applications

Data Logging Software Applications are required for maintaining the data log from the various parameters of the Devices / Equipments in the Real Time and Offline Mode. Software will be designed to communicate with the Device with a particular protocol which Device supports. Also, with the same protocol, one can configure multiple devices in the Software for Data Logging. Various Modules are there given below along with screen shots of important events. These Applications can be developed with or without Pharma Part 21 Compliances. Desktop Interface as well as Web Interface (With Internet or Intranet) can be used to develop these Applications. We can use OPC Interface (OPC HDA, OPC DA, OPC UA & OPC AE), Modbus TCP/IP, Modbus RTU, PLC Interface, Modbus Ascii, Ethernet Communication,SNMP, UDP,Ascii Communication, Any Customized protocol for Communication with Device / Instrument

Master

Data Process

Analysis Report

Admin Utility

OPC Interface Applications

OLE for Process Control. OPC is a software interface standard that allows Windows programs to communicate with industrial hardware devices. OPC is implemented in server/client pairs. The OPC server is a software program that converts the hardware communication protocol used by a PLC into the OPC protocol. We have developed many Interface Applications using OPC Protocols. Below are the Types of OPC's used in Projects:

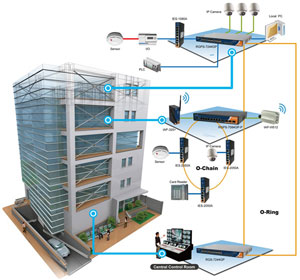

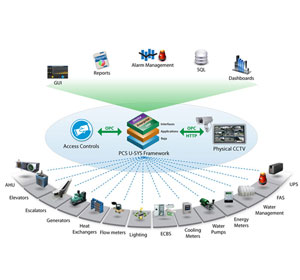

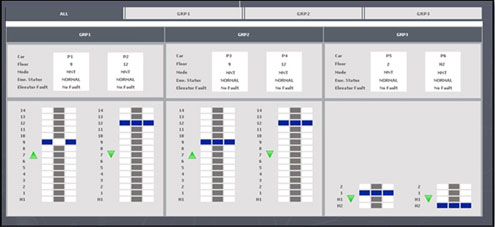

Intelligent Building Management Systems (IBMS)

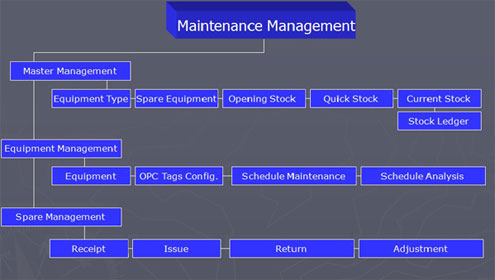

Building Management System (BMS) is taken one step further by us by developing a complete Softawre / Web Portal where in all the signals and device outputs given by various modules in BMS are tagged in an OPC Server and our portal will take the Signals from the same and compute / display the status of the different devices in real time / offline on screen. Since ours will be a Database Application, outputs taken from OPC Server or any other Interface are stored on Database and relevent Analysis reports are generated. Also, we have few modules for data entries and analysis which are additional part of the Software / Web Portal. Some of the Modules Covered are : OPC Tag Configuration & Monitoring, Asset & Maintenance Management, Help Desk, Facility Booking, Utilities Monitoring, Tanent Billing, Global Directory etc.

Building automation describes the advanced functionality provided by the control system of a building. A building automation system (BAS) is an example of a distributed control system. The control system is a computerized, intelligent network of electronic devices designed to monitor and control the mechanical, electronics, and lighting systems in a building. BAS core functionality keeps the building climate within a specified range, provides lighting based on an occupancy schedule, monitors system performance and device failures, and provides malfunction alarms (via email and/or text notifications) to building engineering/maintenance staff. The BAS functionality reduces building energy and maintenance costs when compared to a non-controlled building. A building controlled by a BAS is often referred to as an intelligent building or a smart home.

Building Automation System is taken one step further by us by developing a complete Softawre / Web Portal where in all the signals and device outputs given by various modules in BMS are tagged in an OPC Server and our portal will take the Signals from the same and compute / display the status of the different devices in real time / offline on screen. Since ours will be a Database Application, outputs taken from OPC Server or any other Interface are stored on Database and relevent Analysis reports are generated. Also, we have few modules for data entries and analysis which are additional part of the Software / Web Portal.

Salient Features

Modules in IBMS

Browser Application Feature

Administration:

Local and Remote data Backup Path. 3 Version of file will be maintained for Day before yesterday, Yesterday, Today

Backup Date and Time

Header Footer details

SMTP Settings

OPC Tag Configuration & Monitoring:

Asset & Maintenance Management:

Help Desk:

Facility Booking:

Global Directory:

Data Fetching Application Feature

This Application installed on the server. This application will perform read write operation for OPC Tag monitoring and auto functionality.

Salient Features

Development Includes:

Customized Device Interface Applications

Paryana Automation has developed Specific Customized Device Interface Applications for many esteemed clients as per their requirements. Paryana Automation acts as an OEM Application Development Company for them and we provide complete support for Installation of the Application at their Client's Units. Thus as OEM, we have successfully installed more then 500 Applications in many large scale multinationals. We will provide Analysis to Implementation Solution for Customized Software Solution.

Part 21 CFR Highlights

21 CFR is the part of Title 21 of the Code of Federal Regulations that establishes the United States Food and Drug Administration (FDA) regulations on electronic records and electronic signatures (ERES). Compulsorily used in Pharma Industry, Paryana Automation has achieved full compliance in Industrial Software Application with 21 CFR.

a) Review Data Log.

b) Approved Data Log.

Bridging & Reporting Applications

Bridging & Reporting Applications are very customized Applications development in which the requirements are like there is a Source of Data Available in form of: Device / Equipment / PLC / XLS Format Files / CSV Format Files / OPC Interface / Serial Communication / FTP / SAP File / XML File etc. Client may want these data to be computed / worked up on and transfer them to other Output Systems like: PLC / OPC / Database etc. In such requirements, we have to understand the nature of Data Computations and develop a Bridge Application which will take the data from Source: Compute / Work on the same ;Supply the changed format data to Destination depending on the system requirements. In large scale installations and plants where Automation is present, such many Bridging Applications are required to be built. We have expertise on the same. We can understand the format of each type of data available and have successfully bridge them to various other formats as shown in the pictures below. In case of Reporting Applications, we have to study the Source of Data ; take those data generated in a Database and then generate various types of Analysis Reports from the database. Some times, its not only interface application, after the data is picked up from Source, there are some data entries being done and then Reports are generated so it can be a mix project of Bridging and Reporting Application as well, we study the requirement and then give the proper solution. Technologies used for development will be either VB.NET or ASP.NET with MS SQL Server as Database or MS ACCESS as Database depending on the requirements.

SMS / Email / Voice Alarm Applications

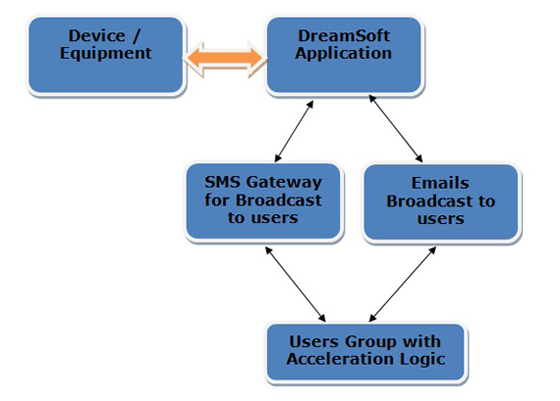

Paryana Automation specializes into Device Interface based SMS and Email Applications where our application will be connected via device followed protocol to the device or equipments and as per the defined Alarm or Interrupt configurations, application at desired point can send SMS / Email to a group of users. SMS / Email is sent from application in Manual and Auto Modes. Voice Alarm can also get generated and we have designed Application to convert Text into Voice. There is a Alarm acknowledge module as well where users will be able to do the acknowledgement. Also features like acceleration are provided for multiple level of users. This is a very intelligent system for any critical or non critical industrial processes or devices / equipments.

Salient Features

Configuration Utility

Admin Utility

SMS Application

Project Design

Paryana Automation's Core competency is and will be in Analysis, Development Cycle & Implementation for various Web Based and Desktop Based Software Solutions in various fields. But after mastering the art of the Software Project Cycle, we have been able to guide the clients with the complete design of the Automation Process. After understanding the clients requirement, we can guide them which Automation Devices like PLC's, OPC Servers etc. will be or won't be required and what should be the flow of the logic for the same, integration of protocols with Devices and Equipments is one thing but getting specialized into which PLC or Logic Controller should be used is something which requires overall System Design Expertise.We have guided many clients with right advice and with practicality for their Device / Equipment / Automation Projects implementation. We have taken up many projects in which design consultants have used wrong methodology / concept and we have entered in that situation and changed the logic and have given successful implementation. Now with our experience, we can even help client in outsourcing right hardware vendor for Automation Devices and Equipments. Many times, as a Software Developer, its not our role to get into the consultancy of Hardware Design or suggesting some Hardware to client, but if we feel that better solution can be derived after changing the system, we do suggest our ideas to client. This is the reason, our clients don't want to leave us and want to use our expertise in various domains. We work as third party vendor too in many project implementations. We work seamlessly with the other teams working on the same project and integrate our solutions with them. Please do let us know if you need any consultation for End to End Project requirements too.